Electrical Welding

Electrical Welding, means the joining of two metals placed together by heating them to melting point by the use of electrical energy.

Advantages of Welding:

- A welded joint is as strong as the base metal.

- Welding equipment is not costly and is portable.

- Welding permits considerable freedom in design.

- Welding products are lighter and strong.

- Welding joint are easier to inspect.

- A large number of similar and dissimilar metals and alloys can be welded

Disadvantages:

- Welding process requires skilled operators.

- Welding process gives harmful radiation and fumes.

- Welding requires edge preparation.

- Welding results in residual stress and needs heat treatment to relieve the internal stresses

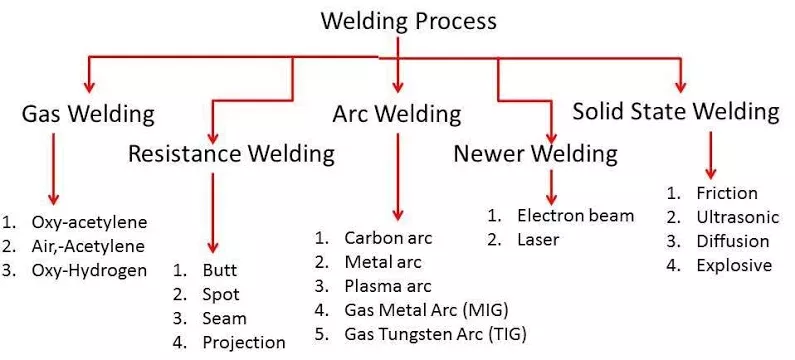

Types of Welding

Resistance Welding:

In this type, heat required for the purpose of weld is produced by the resistance offered to the flow of current at the junction of two metals ie, I2Rt Loss. Resistance welding can be mainly classified into,

- Spot welding

- Seam welding

- Butt welding

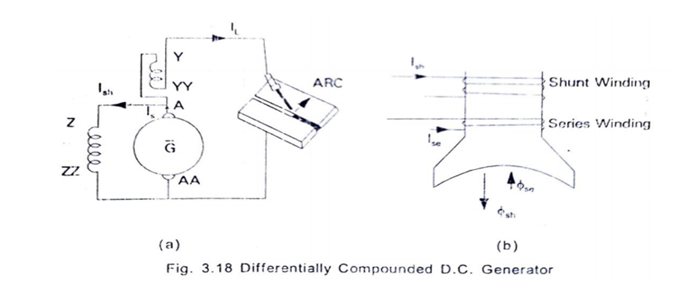

Welding Generator

A differentially compounded D.C generator is used as welding generator. In this generator series field and shunt field windings are wound in opposite directions so that their fluxes oppose each other. The net field flux and the generated voltage are reduced as load current increases. Thus the generator has drooping V- I characteristics. Drooping means that the terminal voltage of welding machine decreases as the welding current increases. Reverse happens when load current decreases.

Recent Comments