Gas Turbine Power Station Working

Gas Turbine Power Station

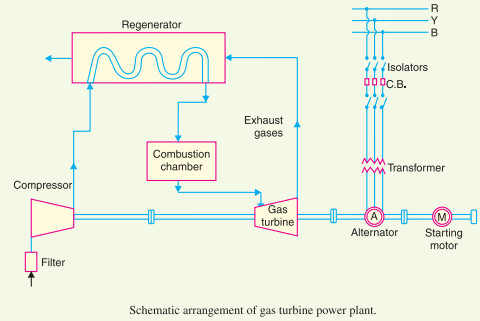

A generating station which employs Gas turbine as the prime mover for the generation of electrical energy is known as Gas Turbine Power Plant It is a type of internal combustion engine. It uses a combination of compressed air and fuel to produce energy.

In Gas Turbine Power Plant, air is used as working fluid. The air is compressed by the compressor and is led to the combustion chamber, In the combustion chamber heat is added to the air by burning oil. The hot and high pressure gas from the combustion chamber is then passed to the gas turbine where it expands and does the mechanical work. The gas turbine drives the alternator which converts mechanical energy into electrical energy.

- Compressor: The compressor used in the plant is generally of rotatory type. The air at atmospheric pressure is drawn by the compressor via the filter which removes the dust from air. The rotatory blades of the compressor push the air between stationary blades to raise its pressure. Thus air at high pressure is available at the output of the compressor.

- Regenerator: A regenerator is a device which recovers heat from the exhaust gases of the turbine. The exhaust is passed through the regenerator before wasting to atmosphere. A regenerator consists of a nest of tubes contained in a shell, The compressed air from the compressor passes through the tubes on its way to the combustion chamber. In this way, compressed air is heated by the hot exhaust gases.

- Combustion chamber: The air at high pressure from the compressor is led to the combustion chamber via the regenerator. In the combustion chamber heat is added to the air by burning oil. The oil is injected through the burner into the chamber at high pressure to ensure atomization of oil and its thorough mixing with air. The combustion gases then delivered to the gas turbine.

- Gas turbine: The products of the combustion gases at high temperature and pressure are passed to the gas turbine. These gases in passing over the turbine blades expand and thus do the mechanical work.

- Alternator: The gas turbine is coupled to the alternator. The alternator converts mechanical energy of the turbine into electrical energy. The output from the alternator is given to the bus-bars through transformer, circuit breakers and isolators.

- Starting motor: Before starting the turbine, compressor has to be started. For this purpose, an electric motor is mounted on the same shaft as that of the turbine. The motor is energized by the batteries. Once the unit starts, a part of mechanical power of the turbine drives the compressor and there is no need of motor now.

Recent Comments