Seam weld

Seam weld, is a type of Resistance Welding. It is a series of continuous spot welds.

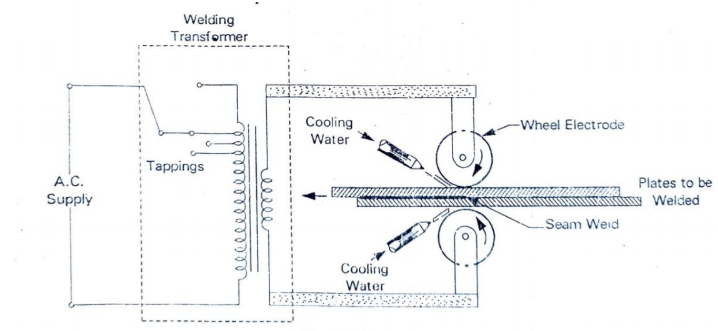

- .In this welding tipped electrodes are replaced by roller electrodes leads the contact area of electrode should be small. This will localize the current & pressure to the welding point.

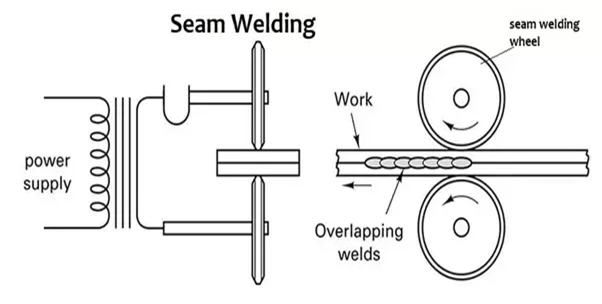

- The two plates to be welded are passed in between roller electrodes.As these rollers travel over the metal pieces which are under pressure the current passing between them heats the two metal pieces to the plastic state and results into continuous spot welds.

- An interrupter used the turn on the supply for a period sufficient to heat the welding point. After the weld, joint is pushed ahead and at the time current is interrupted. Weld joint is cooled by splashing water over it.

- Depending upon the number of welding current pulses per second we get series of weld spots.

- If continuous current is used for welding, there is a tendency for heat build-up and cause burning and warping. Therefore an intermittent current is used to get a seam weld which is actually a series of overlapping spot welds. The number of spots varies between about 24 and 40 per 10 cm, so that if the work piece is travelling at a speed of say 4.6 m/minute, the number of current interruptions will have to be between about 1000 and 1800 per minute.

Applications:

- It is used for pressure tight and leak proof tanks such as transformer radiators, transformer tank/containers etc.

- It is used for making lap and butt joints

Recent Comments