Arc Furnaces

It is a method of electric heating in which charge is heated with the help of heat produced from ARC.

ARC : When the electric supply is given to two electrodes separated in air, air gap is subjected to very high voltage the air gets ionized due to electrostatic forces. The ionized air act as a conducting material, therefore the c starts flowing through the air gap in the form of continuous spark. Ie, ARC.

It is to be noted that a very high voltage is required to establish an arc across an air gap but to maintain an arc small voltage may be sufficient. Alternatively an arc can also be produced by short circuiting the two electrodes momentarily and then withdrawing them back. In this method high voltage is not required.

- Arc furnace having an air gap and electrode. Electrodes may be either carbon or graphite. Air gap dielectric strength is 21.1 kv/cm

- Air in the gap get ionized when high voltage is applied across an air gap. Current flows in the air gap in the form of an arc. Which can be used as source of heating. This is known as arc heating.

- Arc between two electrodes produces heat and has a temperature between 1,000 °C and 3,500 °C depending on the material of the electrodes used.

- Arc furnace are cylindrical & conical shape. Conical shape are mostly used. because of its advantages: Large surface area, Smaller melting time, Smaller radiation losses, Less consumption of power

ELECTRIC ARC FURNACE

It is a furnace in which the charge material is heated by the method of Arc heating. There are two types of electric arc furnaces,

- Direct arc furnace

- Indirect arc furnace.

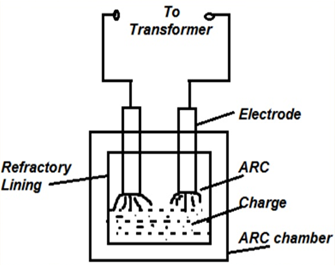

Direct Arc furnace

It consists of two electrodes. When supply is given to the electrodes, two arcs are established and current passes through the charge. The arc is in direct contact with the charge. Heat is developed due to arcs and a small amount of heat is also developed due to the electrical resistance of the charge. Therefore large amount of heat can be generated. For large capacity furnaces, 3-phase supply is used. The most important feature of the direct arc furnace is that, the current passing through the charge develops electromagnetic forces and necessary stirring action is automatically obtained by it. This result in uniform heating of the charge.

Application – Refining and melting of Steel

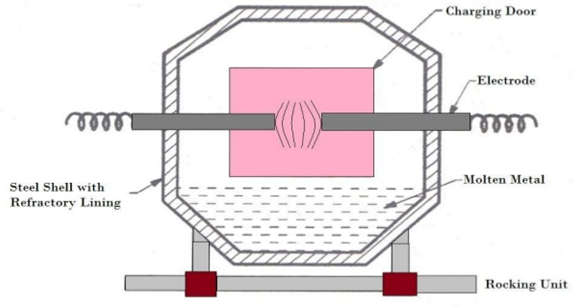

Indirect arc furnace

- In this type of furnace the arc exists between two electrodes and there is no direct contact between arc and charge. Made up of steel with refractory lining inside

- Arc is formed above the charge. heat developed in the charge is purely by the radiation from the arc.

- The temperature of the charge is lower than that in the direct arc furnace. As current does not flow through the charge, there is no stirring action.

- The furnace must be rocked mechanically. An electric motor is used to operate suitable grinders and rollers to provide rocking action to the furnace. Rocking action helps in thorough mixing and uniform heating of the charge. Hence, these furnaces are also known as rocking arc furnaces.

- Only used in single phase AC supply

- Economical

Application – Melting of non-ferrous metals (does not contain iron, eg: Al,Cu,Zn)

Recent Comments