Electric Heating:

- Electric heating is a process in which electrical energy is converted to heat energy. Common applications include space heating, cooking, water heating and industrial processes.

Heat can be produced by,

- Circulation of current through a resistance

- Production of an arc between two electrodes

- Induced eddy currents

- Hysteresis loss in a magnetic material

- Dielectric loss in an Insulating material

Advantages of Electric Heating

- Cleanliness – Completely eliminate dust & ash

- No pollution – absence of flue gases

- Ease of control – manual or fully automatic control of heat is possible

- High temperature

- Uniform heating – conducting or non conductive material can be heated uniformly

- Localized heating is possible

- High efficiency – The over all efficiency of electric heating is high, since the heat can be produced directly in the charge itself.

- Low attention needed

- Less Floor area is required – electric furnace is more compact

- Better working conditions – no irritating noise

- Economical -electric furnaces are cheaper in their initial cost as well as maintenance cost, do not require big space for installation or for storage of coal and wood, no need to construct any chimney

- No carrying expense.

Requirements of Good heating Material

- High Resistivity : This will reduce the length of the heating element.

- Low temperature coefficient of resistance : Lower the temperature coefficient of resistance of the material smaller the variation of resistance

- High melting point : It’s melting point should be sufficiently higher than its operating temperature otherwise, a small increase in temperature will destroy the element.

- Free from oxidation : The element material should not oxidise at high temperatures. Formation of oxidised layers will shorten its life.

- Non corrosive : The element should not corrode when exposed to atmosphere or any other chemical fumes.

- Ductile : It helps in obtaining different shapes and sizes of the element

- High mechanical strength : The element should possess high mechanical strength and should withstand vibrations.

- Economical : The cost of the material should not be high.

Materials used for Electric Heating

- NICHROME : Alloy of Nickel & Chromium

- EUREKA / CONSTANTAN : Alloy of Nickel & Copper

- KANTHAL : Alloy of Iron, Chromium & Aluminium

Different Modes of Heat Transfer

The transmission of heat from one body to another because of the temperature gradient takes place by any of the following methods.

Conduction, Convection & Radiation

1. Conduction : In conduction, heat flows from object with higher temperature to object with lower temperature without the movement of molecules. Happens in solids liquids and gases. In solid, heat is passed on to next neighboring molecules without shifting any transfer of molecules. Conduction is more predominant in solids.

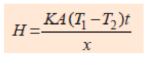

Consider a solid material of cross-section A and thickness x metre If T1 and T2 are the temperatures of the two sides of the slab in °K, then heat conducted between the two opposite faces in time t seconds is given by:

Eg : Ironing of clothes is an example of conduction where the heat is conducted from the iron to clothes.

2.Convection : In convection heat transfer takes place from higher temperature regions to lower temperature regions due to actual motion of molecules. Prominent in liquids.

Example : Boiling of water – molecules that are denser move at the bottom while the molecules which are less dense move upwards resulting in circular motion of the molecules so that water gets heated.

3. Radiation : Radiation is a method of heat transfer that does not require a medium between the heat source and the heated object. Radiation takes place through a vacuum or transparent medium (solid or liquid).Radiation is a form of energy transport consisting of electromagnetic waves traveling at the speed of light. Movement of charged electrons and protons is responsible for the emission of electromagnetic radiation. These electromagnetic waves carry away the energy from the emitting body and when they incide on another body the energy gets released to that object.

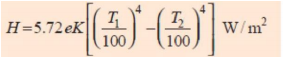

According to Stefan’s law of radiation the heat dissipation H

Ex :Microwave radiation emitted in oven , UV rays coming from the sun is an example of radiation.

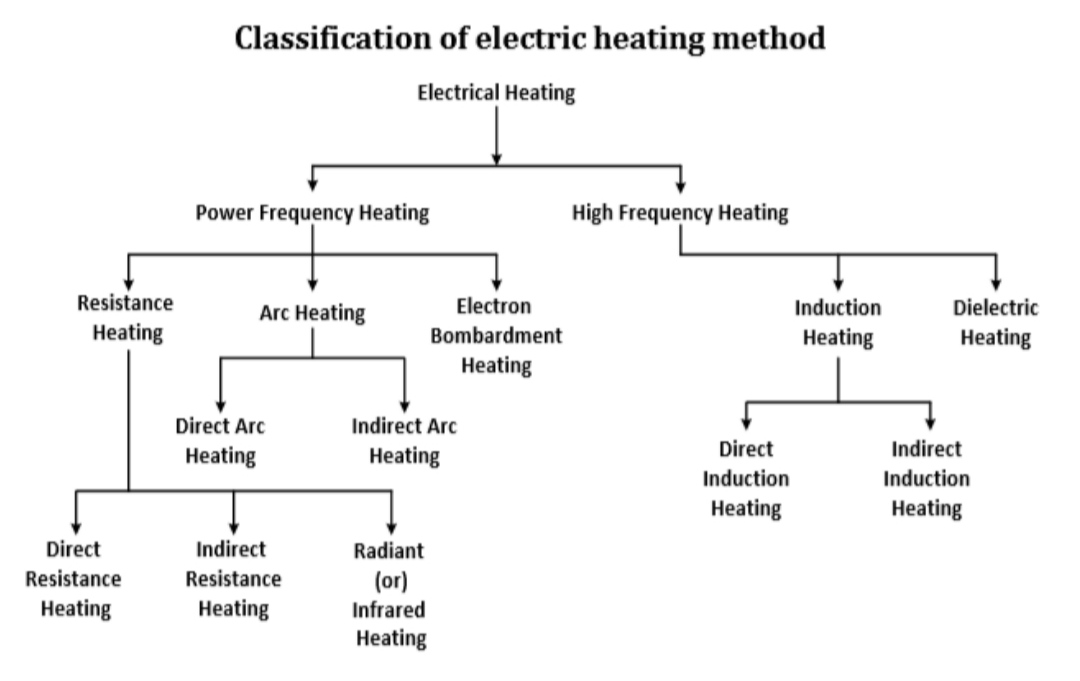

ELECTRIC HEATING METHODS:

Power frequency heating

Normal frequency current is passed to the heating element. Power loss in the form of heat is transferred from the heating element to the material to be heated (charge) either by convection, conduction or radiation. Heat transfer by these conventional methods is very small. Amount of heat transferred by convection is 0.5 watt per square c.m, by radiation is 80 watt per sq.cm. and by conduction is 20 to 1000 watt per sq. cm. Low frequency heating is of two types,

- Resistance heating – power loss (ohmic heat loss) in the high resistance heating element is used to heat the charge

- Arc heating – heat energy of electric arc is used to heat the charge

High frequency heating

conversion of electromagnetic energy into heat energy takes place in the material itself in the form of eddy current loss and dielectric loss. Heat transfer by high frequency heating is as much as 10,000 watt per sq.cm. Based on type of materials to be heated high frequency

heating is of two types,

- Induction heating – for heating conducting materials (Ferromagnetic and non-magnetic)

- Dielectric heating – for heating insulating materials

Types of Resistance Heating

When current passes through a resistance, power loss takes place and it appears in the form of heat. All the electrical energy given to a resistance heating element will be converted into heat energy .

The resistance heating is further classified as,

Direct resistance heating, Indirect resistance heating, Infrared or Radiant heating

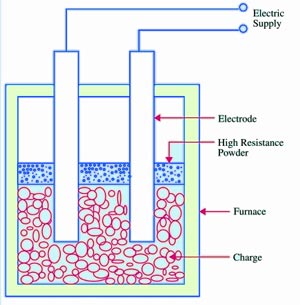

1: Direct resistance heating : In this method of heating, current is passed through the material or charge to be heated. The charge is taken in a furnace and two electrodes (or three electrodes for 3-phase) are immersed in the charge. The supply a c or d.c. will be given to the electrodes as shown in figure. The charge may be in the form of solid/metal pieces, powder or liquid. When solid/metal pieces are to be heated a powder of high resistivity material is sprinkled over the surface of the charge to avoid direct short-circuit. The resistance offered by the charge to the flow of current causes power loss I2R and it results in the heating of the charge.

This method provides high and uniform temperatures. This method has quiet high efficiency since heat is produced in the charge itself.

Application : Resistance welding , Electrode boiler for heating water

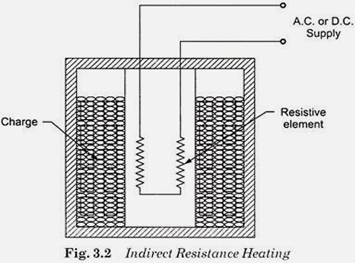

2. Indirect resistance heating : In this method the current is passed through a high resistance wire known as heating element as shown in figure. The heating element is placed inside a chamber so that there is no direct contact between the charge and heating element. Usually charge will enclose the heating element for efficient heat transfer. The heat produced in the element is transferred to the charge by radiation or convection methods.

This method provides uniform temperature. Automatic temperature control can be provided in this method.

Application: room heaters , immersion water heaters , various types of resistance ovens used in domestic cooking.

Recent Comments