Construction of 3 phase induction motor

Explain the Constructional details of 3 phase induction motor

A 3 phase induction motor has two main parts, Stator and Rotor. The rotor is separated from the stator by a small air gap which ranges from 0.4 to 4mm, depending on the power of the motor.

Stator:

Stationary part of the machine is called stator.

Stator frame:

- Stator frame is the outer protecting part of the motor, made up of Cast iron or cast steel.

- Main function of the stator frame is support the stator core and provides protection and mechanical strength of all inner part of the machines.

Stator Core and Winding:

- It is an outer, stationary, hollow cylindrical structure made up of thin laminations of silicon steel having slots on the inner periphery.

- Laminated silicon steel used to reduce hysteresis and eddy current loss.

- The insulated copper conductors placed in the stator slots and are suitably connected either in star or delta depending upon which type of starting method we use.

- 3phas stator winding is wound for a definite number of poles as per the requirement of speed.

- 3 phase ac supply is applied to the 3 phase winding, produce a rotating magnetic field running at synchronous speed.

Rotor:

Rotating part of the motor, made up of laminated silicon steel mounted on the shaft. It is a hollow core having slots on its outer periphery. Copper or aluminium windings placed in these slots. Mainly two types construction for the rotor are available,

Squirrel cage rotor:

- Most used type of induction motor, because of simple and rugged construction.

- It consists of laminated cylindrical core having slots on its outer periphery, slots are not parallel to the shaft axis they are skewed at a certain angle. A thick copper or aluminium bars are placed in each slots.

- All these bars are permanently joined together at both ends by metal rings called end rings.

- The rotor bars and end rings together resembles the cage of a squirrel and hence the name.

- Rotor is not electrically connected to the supply but has current induced in it by transformer action from the stator.

- These type rotor motor have low starting torque, because of no addition any external resistance to the rotor circuit.

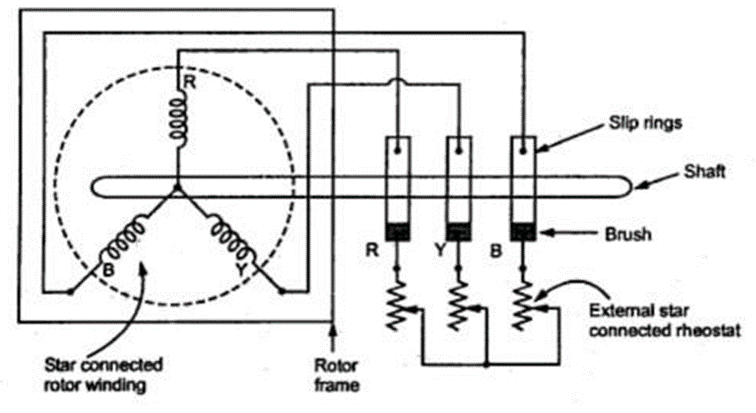

Slip ring rotor/Phase wound rotor:

- It consists of laminated cylindrical core having skewed slots on its outer periphery, Carries three phase windings connected either in star or delta.

- The open end terminals of the rotor windings are brought out and joined three insulated slip rings mounted on the rotor shaft, which are in contact with stationary brushes.

- Three brushes are further externally connected to a 3 phase star connected rheostat.

- At starting external resistance are added in the rotor circuit to give high starting torque, these resistance are gradually reduced to zero and slip rings are automatically short circuited by means of metal cooler in running condition.

- These metal cooler lifted the brushes and connect all the slip rings together to reduce frictional loss and the wear and tear.

Recent Comments