Electric Braking – Rheostatic braking

The process of applying brakes and reduce the speed of any moving or rotating equipment can be termed as braking.

- Mechanical Braking

- Electrical Braking

Types of Electric Braking

- Rheostatic / Dynamic braking.

- Regenerative Braking.

- Plugging type braking.

Advantages of Electric Braking

- Electric braking is fast and cheap.

- It reduces the wear and tear of the brake shoe.

- It produces higher rate of retardation.

- No replacement of brake shoe.

- Heat produced is not failure to the braking system.

- Smooth and without shock.

- Do not produce metal dust.

- The part of energy is returned to the supply thereby effecting , a considerable saving in the operating cost

- By using electric braking the capacity of the system (like higher speeds, heavy loads) can be increased.

- In electric braking negligible amount of heat is generated whereas in mechanical braking enormous heat is produced at brake shoes which leads to failure of brakes.

- If regenerative braking is used, the electrical energy generated during braking is pushed back to supply source. The energy consumption and operation cost are considerably reduced

Rheostatic / Dynamic braking.

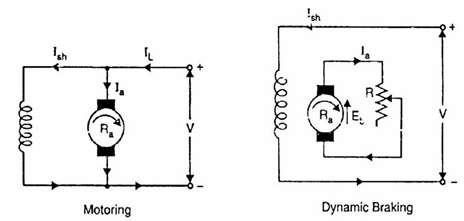

In this type, motor is disconnected from the supply and run as a generator driven by the remaining KE of the equipment, ie by the energy stored in the motor and load which are to be braked. Across this generator is connected the resistive loads which is gradually increased and the generator output is dissipated.ie, braking resistor Rb is connected across the armature as soon as the DC motor is disconnected from the supply mains. The motor now works as a generator, producing the braking torque.

Shunt Motor:

Armature is simply disconnected from the supply and is connected to a resistance in series with it, the field winding remains connected to the supply. The braking torque can be adjusted suitably by varying the resistance in the armature circuit. In case supply fails, the field disappears and there is no braking torque.

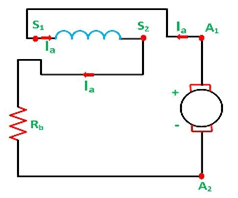

Series Motor:

The motor after disconnecting from the supply is made to run as a c series generator. The resistance is inserted in the circuit must be less than the critical resistance otherwise the generator will not be self-exciting. When the series motor is disconnected from the supply, the direction of the armature current is reversed, therefore the field connections must be reversed in order to allow the flux to build up.

Recent Comments