Individual Drives & Group Drives

classification of Electric Drives

- Individual drive:- If one motor is used to drive one load.

- Group drive:– When several machines are run on one shaft and the shaft is driven by a single motor is called group drive.

- Multi motor Drive:– Separate motors are used for operating different parts of the same mechanism.

Individual drive

If one motor is used to drive one load.

Advantages :

- A fault in the motor will not idle the other loads.

- The motor almost run always with full load, so high efficiency.

- It eliminates all shafting and belting.

- Machines can be installed at any desired place.

- Addition of future loads is easy.

- The speed control of individual load is easy.

- The system is very safe.

- The noise level is less.

- The appearance is good.

- Motors operate at good power factor.

Disadvantages:

- The fixed or initial cost is high.

- It is not suited for a sequence of operations.

- The over load capacity of each motor will be less.

Group drive:-

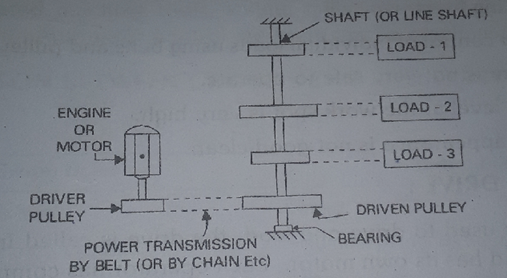

When one prime mover or motoris used for the number of machine tools on common shaft then the drive is called as group drive. it is also sometimes called as shaft drive. The Group Drive system uses a high powered motor which drives an overhead shaft called the main shaft by means of chain or belt. The main shaft runs across the workshop from one end to other ends. The main shaft drives another shaft called counter shaft. Finally, the counter shaft drives the group of machines through belting and pulleys.

Advantages :

- Cost of group drive is less for given capacity of load. cost of one motors of given capacity is less than the cost of many motors of the same capacity.

- Group drive has high overload capacity.

- Only one motor is to be handled.

- By proper load adjustment, it is possible to operate the motor at almost full load.

- The rating of the motor can be less than the sum of all loads used.

Disadvantages:

- The breakdown of main motor causes stoppage of all the operations. Considerable power loss takes place in the energy transmitting system.

- It is used in the process where stoppage of one operation requires the stoppage of sequence of operations as in case of textile mills.

- Speed control of individual machine is very difficult.

- Flexibility of layout of the various machines is lost in group drive since machines have to be installed to suit the layout of the line shafting.

- Extension of the process by installing new machine is limited.

- Group drives are less safe to operate.

- The noise level at the work spot is very high.

- If only small load is to be used, the motors has to work with light loads . his results in reduced efficiency.

- It does not give good appearances due to use of line shafting pulleys and belts.

- The drive appearance is not clean.

Comparison between Individual Drives and Group Drives

| Individual Drive | Group Drive | |

| Initial Cost | High | Less |

| Flexibility | More Flexibility | Less Flexibility |

| Safety | It is more safe | It is less Safe |

| Reliability | It has high reliability | It has less reliability |

| Space required | More | Less |

| Overload Capacity | Less | Higher |

| Maintenance cost | More | Less |

| Speed control | Easily possible | Difficult |

| Mechanical Power transmission losses | Less losses | More Losses |

| Addition/Alternation | Easily possible | Easily not possible |

| Total HP | More | Less |

| Appearance | Good | Not good |

| Any one application of each | Lathe Machine | Textile Industry |

| Number of motors equal to number of machines. | Single large motor is used. |

Recent Comments