Spot welding

Spot welding is a type of Resistance Welding.It is usually employed for joining sheet metal structure.It Only provides mechanical strength and is not air or water tight.

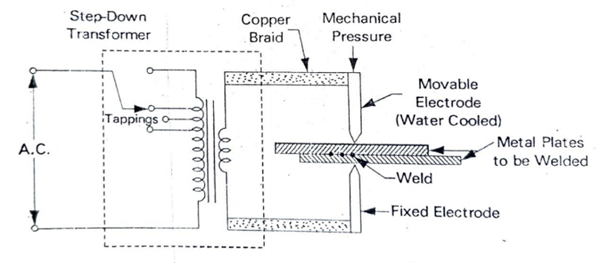

- The workplace or plates to be welded are held between two electrodes and pressed together by mechanical pressure exerted through electrodes.

- The current is passed for a definite period of time, dependent upon the size of the plates. The heat produced between the workplace produce a spot weld.

- The unwanted heat generation between electrodes and work places is to be avoided either by water cooled electrodes.

- The welding current depends on the thickness and composition of the work pieces. It varies from 1,000 to 10.000 ampere at low voltage of the order 1 to 15 volt.

Applications:

- It is used for fabricating sheets where mechanical strength is important rather than air or water tight

- It is used in all types of boxes and enclosing cases etc

Recent Comments