Vacuum Circuit Breaker (VCB) & Sulphur Hexaflouride Circuit Breaker

Vacuum Circuit Breaker (VCB):

- Vacuum used as an arc quenching medium. The operation of switching on and closing of current carrying contacts and interrelated arc interruption takes place in a vacuum chamber in the breaker which is called vacuum interrupter

- Vacuum offers the highest dielectric strength ie, 170 kV.

- When contacts of a breaker are opened in the vacuum, the interruption occurs at first current zero with dielectric strength between the contacts building up at a rate thousands of times higher than that obtained with other types of circuit breakers.

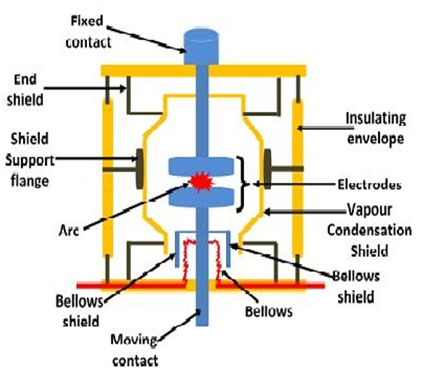

Construction:

- It consists of fixed contact, moving contact and arc shield mounted inside a vacuum chamber (vacuum interrupter). Metal end cap attached upper and lower part of the contacts

- The movable member is connected to the control mechanism by stainless steel bellows. This enables the permanent sealing of the vacuum chamber so as to eliminate the possibility of the leak.

- A glass vessel or ceramic vessel is used as the outer insulating body envelope for observation.

- The arc shield prevents the deterioration of the internal dielectric strength by preventing metallic vapors from falling on the inside surface of the outer insulating cover.

Working:

The pressure inside the vacuum interrupter is maintained below10^-4 torr.When the breaker operates, the moving contacts separates from the fixed contact and an arc is struck between the contacts. The production of arc is due to the ionization of metal ions depends very much upon the material of contacts. The arc is quickly extinguished because the metallic vapours, electrons and ions produced during arc are diffused in a short time and seized by the surfaces of moving and fixed members and shields. Since vacuum has very fast rate of recovery of dielectric strength, the arc extinction in vacuum breaker occurs with a short contact separation (0.625).

Advantages of Vacuum Circuit Breaker :

- There are no fire hazards

- Pollution less, There is no generation of gas during and after operation.

- Little require little maintenance and are quiet in operation.

- Reliable and have longer life.

- Application ranging from 22kV to 66 Kv.

- Can be used for frequent switching.

- They can interrupt any fault current.

- They can successfully withstand lightning surges.

- Best interrupting low current applications such as shunt reactor switching, transformer switching, capacitor bank switching.

Sulphur Hexaflouride Circuit Breaker

- sulphur hexafluoride (SF6) gas is used as the arc quenching medium.

- The SF6 is an electro-negative gas and has a strong tendency to absorb free electrons. The contacts of the breaker are opened in a high-pressure flow of SF6 gas and an arc is struck between them. The conducting free electrons in the arc are rapidly captured by the gas to form relatively immobile negative ions. This loss of conducting electrons in the arc quickly builds up enough insulation strength to extinguish the arc.

- It is colourless, odourless, non-toxic, and non-inflammable gas.

- SF6 gas is extremely stable and inert, and its density is five times that of air.

- It has high thermal conductivity better than that of air and assists in better cooling current carrying parts.

- It has a unique property of fast recombination after the source energising spark is removed. It is 100 times more effective as compared to arc quenching medium

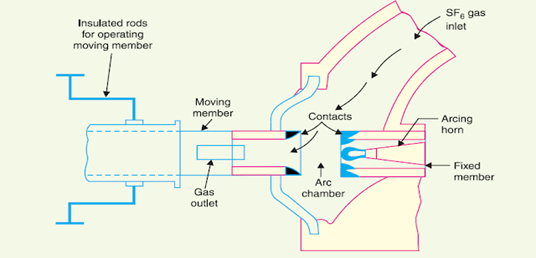

Construction :

SF6 circuit breakers mainly consist of two parts, namely (a) the interrupter unit and (b) the gas system.

Interrupter Unit – This unit consists of moving and fixed contacts are enclosed in a chamber containing SF6 gas. When the contacts of the breaker are opened, the valve mechanism permits a high pressure SF6 gas from the reservoir to flow towards the arc interruption chamber. The fixed contact is a hollow cylindrical current carrying contacts fitted with an arc horn. The moving contact is also a hollow cylinder with rectangular holes in the sides to permit the SF6 gas to let out through these holes after flowing along and across the arc. The tips of fixed contact and moving contacts and arcing horn are coated with copper – tungsten arc resistance material.

Gas System – The closed circuit gas system is employed in SF6 circuit breakers. The SF6 gas is costly, so it is reclaimed after each operation. This unit consists low and high-pressure chambers with a low-pressure alarm along with warning switches. When the pressure of the gas is very low due to which the dielectric strength of gases decrease and an arc quenching ability of the breakers is endangered, then this system gives the warning alarm.

Working Principle of SF6 Circuit Breaker

In the normal operating conditions, the contacts of the breaker are closed. When the fault occurs in the system, the contacts are pulled apart, and an arc is struck between them. The displacement of the moving contacts is synchronised with the valve which enters the high-pressure SF6 gas in the arc interrupting chamber at a pressure of about 14kg/cm^2.

The high pressure SF6 gas absorbs the free electrons in the arc path and forms ions which do not act as a charge carrier. The result is that medium between the contact quickly increase the dielectric strength and causes the extinction of arc. After the breaker operation the valve is closed by the action of a set of springs, This process reduces the pressure of the SF6 gas up to 3kg/cm^2 thus; it is stored in the low-pressure reservoir. This low-pressure gas is pulled back to the high-pressure reservoir for re-use.

Advantages of SF6 Circuit Breaker:

- SF6 gas has excellent insulating, arc extinguishing and many other properties which are the greatest advantages of SF6 circuit breakers.

- The gas is non-inflammable and chemically stable. Their decomposition products are non-explosive and hence there is no risk of fire or explosion.

- Electric clearance is very much reduced because of the high dielectric strength of SF6.

- Its performance is not affected due to variations in atmospheric condition.

- It gives noiseless operation, and there is no over voltage problem because the arc is extinguished at natural current zero.

- There is no reduction in dielectric strength because no carbon particles are formed during arcing.

- It requires less maintenance and no costly compressed air system is required.

- SF6 performs various duties like clearing short-line faults, switching, opening unloaded transmission lines, and transformer reactor, etc. without any problem.

Disadvntages of SF6 Circuit Breaker:

- SF6 gas is suffocating to some extent. In the case of leakage in the breaker tank, the SF6 gas being heavier than air and hence SF6 are settled in the surroundings and lead to the suffocation of the operating personnel.

- The entrance of moisture in the SF6 breaker tank is very harmful to the breaker, and it causes several failures.

- The internal parts need cleaning during periodic maintenance under clean and dry environment.

- The special facility requires for transportation and maintenance of quality of gas.

Recent Comments