Study of Multimeters and Testing of Components.

STUDY OF MULTIMETERS and TESTING OF COMPONENTS

AIM:

To study the use of multi meter to check voltage, current and also to check various electronic components.

MATERIALS AND TOOLS REQUIRED:

Solder, flux, knife/blade, soldering iron, desoldering pump and nose pliers.

THEORY:

A multi-meter or a multi tester, also known as a VOM (Volt-Ohm meter), is an electronic measuring instrument that combines several measurement functions in one unit. A typical multi meter would include basic features such as the ability to measure voltage, current, and resistance. Analog multi meters use a micro ammeter whose pointer moves over a scale calibrated for all the different measurements that can be made. Digital multi-meters display the measured value in numerals, and may also display a bar of a length proportional to the quantity being measured.

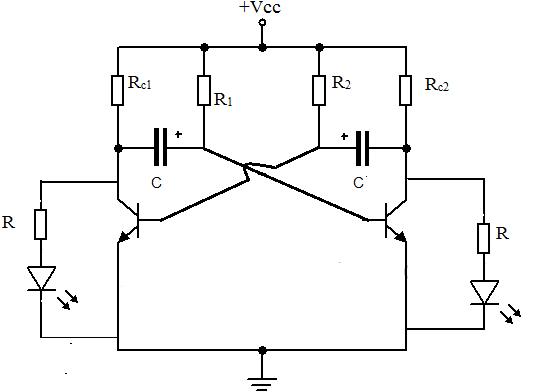

Circuit Diagram:

PROCEDURE:

DIGITAL MULTIMETER

Voltage Measurement

- Connect the red test lead to “V-Ω” input terminal and black test lead to “COM” input terminal.

- Set function/range switch to desired voltage type (DC/AC) and range. If magnitude of voltage is not known, set switch to highest range and reduce until a satisfactory reading is obtained.

- Turn-Off power to the device or circuit being tested and discharge all capacitors.

- Connect test lead to the device or circuit being measured.

- Turn On power to the device or circuit being measured. Voltage value will appear on the digital display along with the voltage polarity.

- Turn Off power to the device or circuit being tested and discharge all capacitors prior to disconnecting test leads.

Current Measurement

- Connect red test lead to the “mA” input terminal for current measurements upto 200mA. Connect black test lead to “COM” input terminal.

- Set function/range switch to desired current type (DC/AC) and range. If magnitude of curent is not known, set switch to highest range and reduce until a satisfactory reading is obtained.

- Turn-Off power to the device or circuit being tested and discharge all capacitors

- Open the circuit in which current is to be measured. Now securely connect test leads in series with the load in which current is to be measured.

- Turn-Off power to the device or circuit being tested

- Read current value on digital display.

- Turn Off power to the device or circuit being tested and discharge all capacitors

- Disconnect test leads from circuit and reconnect circuit that was being tested.

- For current measurement of 200mA or greater, connect the red test lead to “20A” input terminal & black test lead to the “COM” input terminal. If the resistance being measured is part of a circuit, turn off power to the circuit and discharge all capacitors.

Resistance Measurement

- Connect the red test lead to “V-Ω” input terminal and black test lead to “COM” input terminal

- Set function/range switch to desired “Ω” position. If magnitude of resistance is not known, set switch to highest range and reduce until a satisfactory reading is obtained.

- If the resistance being measured is part of a circuit, turn off power to the circuit and discharge all capacitors.

- Connect test leads to the device or circuit being measured. When measuring high resistance, be sure to connect adjacent points even if insulated, because some insulators have a relatively low insulation resistance, causing the measured resistance to be lower than actual resistance.

- Read resistance value on digital display. If a high resistance value is shunted by a large value of capacitance, allow digits to stabilize.

Diode Measurements

- Connect the red test lead to “V-Ω” input terminal and black test lead to “COM” input terminal.

- Set function/range switch to diode test position.

- If the semiconductor junction being measured is a part of the circuit, turn off power to the circuit and discharge all capacitors.

- Connect test leads to the device.

- Read forward voltage value on digital display.

RESULT:

The meters were studied and the components were tested.

Recent Comments