Butt welding

Butt Welding are two types, Upset butt welding & Flash butt welding

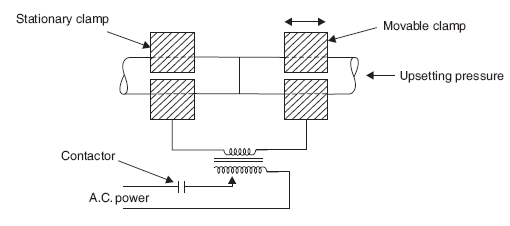

Upset butt welding :

- Two work pieces to be welded together are fixed in clamps and butted against each other.

- Electrodes used are jaw type and these should be in a position to introduce high current without treating any hot spot on the job.

- When supply is switched-on, heavy current passes through the joint and heat is generated by the contact resistance between two work places. When efficient heat is developed, the work pieces are joined by axial force by a spring and produce a butt joint.

Applications:

- It is most suitable for joining metal parts end-to-end or edge-to-edge.

- It is used for rods, pipes and wires.

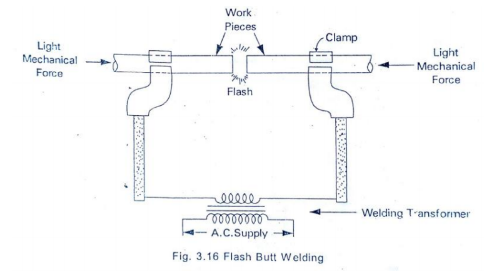

Flash butt welding:

- It is little different from upset butt welding. In this process, the ends of two work piece to be welded are put together under light axial mechanical pressure. A small gap will be remained in between the two work pieces before supply is given. When supply is switched on arcing will takes place. Arcing is allowed till the two ends of the work pieces reach welding/melting temperature, after that the supply will be switched off and the pieces are rapidly brought together with light pressure. As the pieces are moved together, the fused metal and slag come out of the joint making a good solid joint. The thin fin around the joint is removed to produce a sound weld.

- Power requirement is less.

- No speed attention is to be paid to the surface being joined.

Application:

- It is extensively used in production work.

- It is employed for welding chains, rail ends, rolled sections, shaft axles.

- Most metals except lead, zinc, antimony, bismuth and their alloys can be flash welded.

Recent Comments