Separation of No Load Losses in a Single Phase Transformer

SEPARATION OF NO LOAD LOSSES IN A SINGLE PHASE TRANSFORMER

AIM:

- To separate no load losses of a transformer in to eddy current loss and hysteresis loss.

APPARATOUS REQUIRED:

| S.No. | Apparatus | Range | Type | Quantity |

| 1 | Ammeter | |||

| 2 | Voltmeter | |||

| 3 | Rheostats | |||

| 4 | SPST Switch | |||

| 5 | Tachometer |

MACHINES DETAILS:

THEORY :

It is seen that the core losses of transformer includes,

- Hysteresis loss

- Eddy current loss

For a given volume and thickness of laminations, these losses depend on the operating frequency, maximum flux density in the core and the voltage.

The hysteresis loss is given by Steinmet’z relation,

Ph = Kh Bm1.67 f v watts

i.e. Ph = A Bm1.67 f watts …………..(1)

Practically conduct two tests on transformers at two different frequencies f1 and f2, keeping maximum flux density in the core same. Thus the core losses i.e. iron losses can be separated into hysteresis and eddy current losses.

PRECAUTIONS:

- The motor field rheostat should be kept at minimum resistance position.

- The alternator field rheostat should be kept at maximum resistance position.

PROCEDURE:

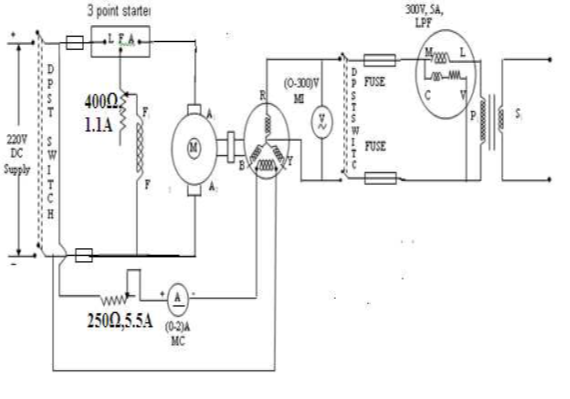

- Connections are given as per the circuit diagram.

- Supply is given by closing the DPST switch.

- The DC motor is started by using the 3 point starter and brought to rated speed by adjusting its field rheostat.

- By varying the alternator filed rheostat gradually the rated primary voltage is applied to the transformer.

- The frequency is varied by varying the motor field rheostat and the readings of frequency are noted and the speed is also measured by using the tachometer.

- The above procedure is repeated for different frequencies and the readings are tabulated.

- The motor is switched off by opening the DPST switch after bringing all the rheostats to the initial position.

CIRCUIT DIAGRAM

TABULAR COLUMN:

| S.No. | Speed N (rpm) | Frequency f (Hz) | Voltage V (Volts) | Wattmeter reading Watts | Iron loss Wi (Watts) | Wi / f Joules |

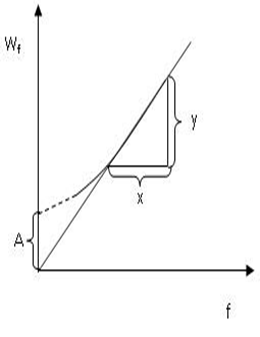

SAMPLE GRAPH :

Recent Comments