Electrical Power Generation, Transmission & Distribution

I Unit – Generation

1. Define Energy?

Capacity to do work is called energy. Unit is Joules.

2. Importance of Electrical Energy.

- Convenient Form: Electrical energy is a very convenient form of energy. It can be converted easily to other forms of energy. Eg: Electrical energy can be converted into light (Bulb), Mechanical energy ( Motor).

- Easy Control: Electrically operated machines can be easily controlled by using switch or other mechanism.

- Greater Flexibility: It can be transported from one place to another with the help of conducted wires.

- Cheapness: It is cheaper than other source of energy for Domestic, Commercial, Industrial applications.

- Cleanliness: It is not associated with smoke or other fumes, poisonous gases.

- High Transmission Efficiency: It can be transmitted efficiently from generating centers to consumers.

3. Compare Conventional & Non-Conventional source of energy?

| Conventional source of Energy | Non Conventional source of Energy |

| These sources of energy are not abundant in nature, Present in Limited Quantity. Eg : Fossil fuels likes Coal , Petroleum,.. | These sources of energy are abundant in nature, Present in Limited Quantity. Eg : Solar, wind, Tidal |

| They are not Replenished/ Restore continuously. They are formed over a million years. | They are Replenished/ Restore continuously by natural process. |

| They are called Non Renewable source of energy. | They are called Renewable source of energy. |

| They can be Exhausted completely due to over consumption. They cannot be reuse. | They cannot be Exhausted completely. |

| They pollute the environment by emitting harmful gases. | They are environment friendly, do not pollute environment. |

| They are commonly used for Industrial & Commercial Purpose. | They are commonly used for house hold purpose. |

| Heavy expensive. | Less expensive. |

| Solar , Thermal, Water Power Generation | Wind, Tidal, Solar, Geo thermal, Wave power |

4. List any two types of Conventional Methods for Electrical Power Generation?

Nuclear, Thermal, Water Power Generation

5. List any two types of Non-Conventional Methods for Electrical Power Generation?

Wind, Tidal, Solar, Geo thermal, Wave power

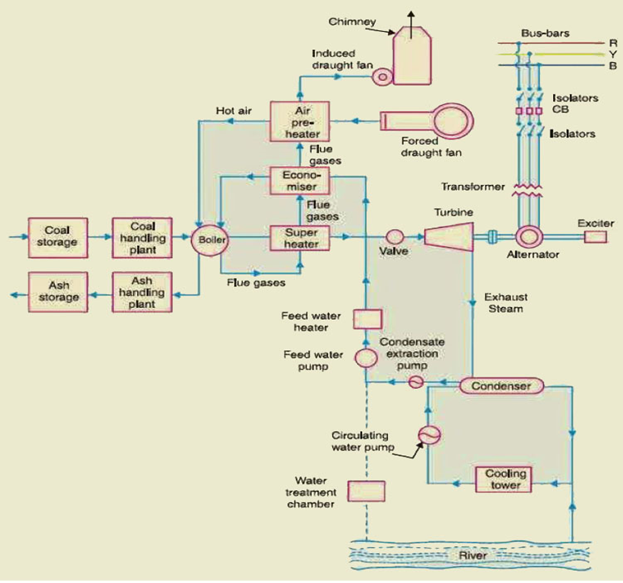

6. Explain the working of Thermal Power Plant with necessary schematic layout and explain the functions of the each components of this power plant?

OR

Draw a labelled schematic diagram of a Steam power plant?

A generating station which converts the heat energy of coal combustion into electrical energy is known as a steam power station.

Steam produced in the boiler by utilizing the heat of coal combustion. The steam is then expanded in the prime mover (steam turbine) and is condensed in a condenser to be fed into the boiler again. The steam turbine drives the alternator which converts mechanical energy of the turbine into electrical energy.

The main components of the power station are,

1. Coal and ash handling arrangement: The coal is transported to the power house and is stored in coal storage plant. It is then delivered to the coal handling plant, where it is crushed into small pieces called Pulverization. In order to increase its surface exposure, gives fast combustion without using large quantity of excess air. The pulverized coal is fed to the boiler by belt conveyors. The coal is burnt in the boiler and the ash produced after complete combustion of coal is removed to the ash handling plant and then delivered to the ash storage plant for disposal.

2. Steam generating plant: This is an important part of steam power station, it includes boiler, boiler furnace, super heater, economizer, air pre-heater…

a) Boiler : A boiler is closed vessel in which water is converted into steam by utilizing the heat of coal combustion. Steam boilers are broadly classified into the following two types, Water tube boilers & Fire tube boilers. In a water tube boiler, water flows through the tubes and the hot gases of combustion flow over these tubes. On the other hand, in a fire tube boiler, the hot products of combustion pass through the tubes surrounded by water.

b) Boiler furnace: A boiler furnace is a chamber in which fuel is burnt to liberate the heat energy. The boiler furnace walls are made of refractory materials such as fire clay, silica, kaolin etc.

c) Super heater: A super heater is a device which super heats the steam, it further raises the temperature of steam. This increases the overall efficiency of the plant. A super heater consists of a group of tubes made of special alloy steels such as chromium molybdenum and placed on the way to the chimney. The steam produced in the boiler is wet & passed through the super heater, it is superheated by the heat of flue gases on their way to chimney.

d) Economiser: It is a device which heats the feed water on its way to boiler by deriving heat from the flue gases. An economizer consists of a large number of closely spaced parallel steel tubes connected by headers of drums. The feed water flows through these tubes and the flue gases flow outside. A part of heat of flue gases is transferred to feed water, thus raising the temperature of the latter. This results in raising boiler efficiency, saving in fuel and reduces stresses in the boiler due to high temperature of feed water.

e) Air Pre-heater: Super heaters and economizers generally cannot fully extract the heat from flue gases. ie, pre – heaters are employed which recover some of the heat in the escaping gases. The function of an air pre-heater is to extract heat from the flue gases and give it to the air being supplied to furnace for coal combustion. This raises the furnace temperature and increases the thermal efficiency of the plant.

3. Steam turbine: The high pressure high temperature superheated steam from the super heater fed to the steam turbine through main valve. The steam energy passing over the blades of turbine is converted into mechanical energy.

4. Alternator: The steam turbine coupled to an alternator. The alternator converts mechanical energy of turbine into electrical energy. The electrical energy output is delivered to the bus bars through transformer, circuit breaker, isolators.

5. Cooling Arrangement: The exhausted steam from the turbine, goes to the condenser which condenses the exhausted steam by means of cold water circulation and maintain a pressure at the exhaust lower than atmosphere. Water is drawn from a river, canal and is circulated through the condenser. The circulating water takes up the heat of the exhausted steam and it becomes hot.

6. Feed water: The condensate from the condenser is used as feed water to the boiler by using feed water pump. The feed water on its way to the boiler is heated by water heaters and economizer. This helps the improving overall efficiency of the plant.

7. State the role of Super heater in Thermal power station?

A super heater is a device which super heats the steam, it further raises the temperature of steam. The steam produced in the boiler is wet & passed through the super heater, it is superheated by the heat of flue gases on their way to chimney.Functions are,

- Improve the overall efficiency.

- Reduce the steam consumption per given output.

- Eliminates the erosion of steam turbine blades due to the absence of moisture.

8. Explain any four site selection factors to install a Steam power station?

- Supply of fuel: The steam power station should be located near the coal mines so that transportation costs of fuel is minimum

- Availability of water: As huge amount of water is required for the condenser, therefore, such a plant should be located at the bank of a river or near a canal to ensure the continuous supply of water.

- Transportation facilities: A modern steam power station often requires the transportation of materials and machinery. Therefore, adequate transportation facilities must exist.

- Labour should be available at reasonable charges at the time of construction of the plant.

- Cost and type of land: The cost of the land should be reasonable and it allow strong foundation to the plant and building. Land should not be rocky and marshy.

- Nearness to load centers: In order to reduce the transmission cost, the plant should be located near the center of the load.

- Distance from populated area : As huge amount of coal is burnt in a steam power station, therefore, smoke and fumes pollute the surrounding areas. This necessitates that the plant should be located at a considerable distance from the populated areas.

9. Indicate the function of Economiser in Thermal power station?

It is a device which heats the feed water on its way to boiler by deriving heat from the flue gases. Functions are,

- Raising boiler efficiency.

- saving in fuel and reduces stresses in the boiler due to high temperature of feed water.

10. Identify the main objective behind the pulverization of coal in Thermal power station?

- In order to increase its surface exposure, gives fast combustion without using large quantity of excess air.

- Low grade coal also can be burnt.

- Boiler can be started quickly.

- No ash handling problems.

- The furnace volume required is less.

- The operation troubles are less.

- Large quantity of steam generation is possible.

- Fast response to load changes.

11. State the use of condenser in Thermal power station?

The exhausted steam from the turbine, goes to the condenser which condenses the exhausted steam by means of cold water circulation and maintain a pressure at the exhaust lower than atmosphere. Water is drawn from a river, canal and is circulated through the condenser. The circulating water takes up the heat of the exhausted steam and it becomes hot.

12. Classify Hydro Power Plant based on Head?

Based on availability of Head of water, Hydroelectric Power Stations are classified into Low Head, Medium Head and High Head Plants.

Low Head Plants: When the operating head is less than 25 meters the plant named as Low Head Plants. This type plant uses Kaplan turbines.

Medium Head Plants: When the operating head of water from 25 to 100 meters the plant named as Medium Head Plants. This type plant uses Francis turbines.

High Head Plants: When the operating head of water exceed 100 meters the plant named as High Head Plants. This type plant uses Pelton turbines.

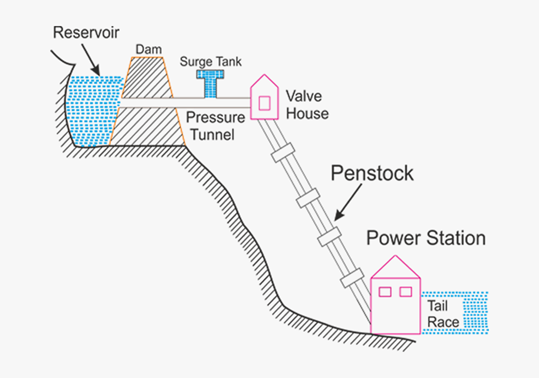

13. Explain the working of Hydroelectric Power Plant with the help of a neat layout?

A Generating station which utilizes the Potential Energy of water at a high level for the generation of Electrical Energy is known as Hydroelectric Power Station.

Hydroelectric Stations are generally located in Hilly areas where dams can be built conveniently and large water reservoirs can be obtained. Hydroelectric stations convert the energy stored in water into electric power by the use of water turbines coupled with generators. The water stored at high altitudes is allowed to pass on the blades of the turbine through penstocks, thus the potential energy and kinetic energy of water is transferred into mechanical energy and then turbine drives the alternator which converts mechanical energy into electrical energy.

Parts of Hydroelectric Power Plant:

- Dam: Dam is constructed across a river or lake, used to store water.\ and create water head. Water from the catchment area collects at the back of the dam to form a reservoir. These are built of concrete, stone masonary….

- Pressure Tunnel: Pressure Tunnel is taken off from the reservoir and water brought to the valve house at the start of the penstock.

- Valve house: It contains Main sluice valves and automatic isolating valves. Main sluice valves controls the water flow to the power house and automatic isolating valves cuts off the supply of water when the penstock bursts.

- Penstock: Penstocks are open or closed conduits, which carry water to the turbines. Generally made up of reinforced concrete or steel. Concrete penstocks are suitable for low heads. Medium and high heads use steel penstocks.

- Surge Tank: Surge Tank is a small reservoir in which is open at the top, It built before the valve house and protects the penstock from bursting (water hammering) in case the turbine gates suddenly close due to the electrical load being thrown off. ie, Surge tank over comes the abnormal pressure in the conduit when the load on the turbine falls and act as a reservoir during increase of load on the turbine.

- Water turbines: Water turbines are used to convert the energy of falling water into mechanical energy. Mainly two types water turbines are available. Impulse turbines & Reaction turbines.

- Spill way: Spill way constructed of concrete piers on the top of the dam & it contains gates. If the river flow exceeds the storage capacity of the reservoir (heavy rain fall) gates are open for the excess water to discharge the downstream.

14. Explain the factors to be considered for the site selection of hydroelectric power station?

1. Availability of water: Sufficient quantity of water at a reasonable head should be available.

2. Storage of water: It should be possible to construct a Dam to store water at the selected site to ensure the generation of power throughout the year.

3. Transportation facilities: power station often requires the transportation of materials and machinery. Therefore, adequate transportation facilities must exist.

4. Labour should be available at reasonable charges at the time of construction of the plant.

5. Cost and type of land: The cost of the land should be reasonable and it allow strong foundation to the plant and building. Land should not be rocky and marshy. Site should allow strong foundations with minimum cost.

6. There should be no possibility of future sources of leakage of water.

7. The selected site should be accessible easly.

15. Discuss the advantages and disadvantages of Hydroelctric power station?

Advantages:

- Water is used for this plant, so fuel cost is zero.

- It is neat & clean.

- Low maintenance cost.

- Simple construction.

- It starts instantly, does not need longer starting time.

- It has longer life time.

- Running charges are very small, because of water is the source of energy.

- This plants are used for irrigation purpose & controlling floods.

Disadvantages:

- High capital cost.

- Skilled & experienced workers are required to build the plant.

- High transmission cost.

- Require huge amount of water at all the time.

16. Explain the function of Surge tank in Hydroelectric Power Plant?

- In case of sudden closing of the fixed gates of the water turbine, due to heavy load being thrown off suddenly the surge tank absorbs the water hammer, by increase its level of water.

- When load on the turbine increases, the additional water is drawn from the surge tank to meet the increased load and act as a reservoir during increases of load on the turbine.

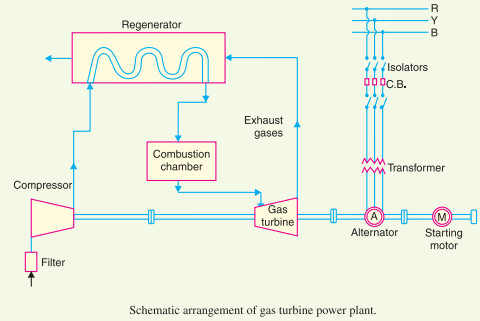

18. Sketch the schematic arrangement of a gas power station and explain the main stages?

A generating station which employs Gas turbine as the prime mover for the generation of electrical energy is known as Gas Turbine Power Plant It is a type of internal combustion engine. It uses a combination of compressed air and fuel to produce energy.

In Gas Turbine Power Plant, air is used as working fluid. The air is compressed by the compressor and is led to the combustion chamber, In the combustion chamber heat is added to the air by burning oil. The hot and high pressure gas from the combustion chamber is then passed to the gas turbine where it expands and does the mechanical work. The gas turbine drives the alternator which converts mechanical energy into electrical energy.

- Compressor: The compressor used in the plant is generally of rotatory type. The air at atmospheric pressure is drawn by the compressor via the filter which removes the dust from air. The rotatory blades of the compressor push the air between stationary blades to raise its pressure. Thus air at high pressure is available at the output of the compressor.

- Regenerator: A regenerator is a device which recovers heat from the exhaust gases of the turbine. The exhaust is passed through the regenerator before wasting to atmosphere. A regenerator consists of a nest of tubes contained in a shell, The compressed air from the compressor passes through the tubes on its way to the combustion chamber. In this way, compressed air is heated by the hot exhaust gases.

- Combustion chamber: The air at high pressure from the compressor is led to the combustion chamber via the regenerator. In the combustion chamber heat is added to the air by burning oil. The oil is injected through the burner into the chamber at high pressure to ensure atomization of oil and its thorough mixing with air. The combustion gases then delivered to the gas turbine.

- Gas turbine: The products of the combustion gases at high temperature and pressure are passed to the gas turbine. These gases in passing over the turbine blades expand and thus do the mechanical work.

- Alternator: The gas turbine is coupled to the alternator. The alternator converts mechanical energy of the turbine into electrical energy. The output from the alternator is given to the bus-bars through transformer, circuit breakers and isolators.

- Starting motor: Before starting the turbine, compressor has to be started. For this purpose, an electric motor is mounted on the same shaft as that of the turbine. The motor is energized by the batteries. Once the unit starts, a part of mechanical power of the turbine drives the compressor and there is no need of motor now.

19. Draw a labelled schematic diagram of diesel power plant and describe its working?

A generating station in which diesel engine is used as the prime mover for the generation of electrical energy is known as diesel power station.

For generating electrical power, it is essential to rotate the rotor of an alternator by means of a prime mover. When prime mover of the alternators is diesel engine, the power station is called diesel power station. The mechanical power required for driving alternator comes from combustion of diesel. As the diesel costs high, this type of power station is not suitable for producing power in large scale in our country. But for small scale production of electric power, and where, there is no other easily available alternatives of producing electric power, diesel power station are used.

Basic Principal of Diesel Electric Power Plant

Chemical Energy of Diesel ↔ Heat Energy ↔ Mechanical Energy ↔Electrical Energy

Main Components of Diesel Electric Power Plant:

1. Diesel Engine: It is the main components used in diesel electric power plant for developing mechanical power. This mechanical power we use to run the generator & produce electrical energy. For producing the electrical energy the diesel engine is mechanically coupled to generator. When the diesel fuel burning inside the engine, its start to produce a mechanical power. The combustion of diesel fuel produces increased temperature & pressure inside the engine. Due to this pressure gases are formed, this gas pushes the piston inside the diesel engine, and then mechanical power is produced. With the use of this mechanical power the shaft of diesel engine starts rotating

2. Engine Fuel Supply System: It consists of Fuel Storage Tank, Fuel Filter or Strainer, Fuel Transfer Pump, Day Tank, Heaters & Connecting Pipes. The diesel fuel stored in storage tank. Then this diesel fuel transfer to day tank, the function of day tank is how much quantity of diesel required for 24 hours is store. If the day tank is full or overflow occurs, then excessive diesel returned to storage tank. The filter or strainer is used to purify diesel. With the help of fuel transfer pump the diesel is transfer to day tank.

3. Engine Air Intake System: The air filters are used to supply the fresh air to diesel engine for the purpose of combustion. Engine required fresh air because, if dust particles in the air entered into the engine will cause disastrous effect to valve, cylinder & pistons.

4. Engine Exhaust System: The exhaust gas is removed from engine, to the atmosphere by means of an exhaust system. A silencer is normally used in this system to reduce noise level of the engine.

5. Engine Cooling System: The heat produced due to internal combustion, drives the engine. But some parts of this heat raise the temperature of different parts of the engine. High temperature may cause permanent damage to the machine. Hence, it is essential to maintain the overall temperature of the engine to a tolerable level. The cooling system is required to carry heat from diesel engine to keep its temperature within safe limits. The water pump circulates water to cylinder of diesel engine to carry away the heat. The cooling tower is used for the same water reused. The cooling system requires a water source, water pump and cooling towers. The pump circulates water through cylinder and head jacket. The water takes away heat from the engine and it becomes hot. The hot water is cooled by cooling towers and is re-circulated for cooling.

6. Engine Lubrication System: This system provides lubricating oil to moving parts of the system to reduce the friction between them wear & tear of the engine parts. This system minimizes the water of rubbing surface of the engine. Here lubricating oil is stored in main lubricating oil tank. This lubricating oil is drawn from the tank by means of oil pump. Then the oil is passed through the oil filter for removing impurities. From the filtering point, this clean lubricating oil is delivered to the different points of the machine where lubrication is required the oil cooler is provided in the system to keep the temperature of the lubricating oil as low as possible. It is then cooled through heat exchanger by means of cold water and then it is fed to the engine.

7. Engine Starting System: For starting a diesel engine, initial rotation of the engine shaft is required. Until the firing start and the unit runs with its own power. For small DG set, the initial rotation of the shaft is provided by handles but for large diesel power station. Compressed air is made for starting.

8. Alternator: The diesel engine is coupled to the alternator. The alternator converts mechanical energy into electrical energy. The output from the alternator is given to the bus-bars through transformer, circuit breakers and isolators.

20. Discuss the merits and demerits of Diesel power station

Advantages of Diesel Power Station

- This is simple in design point of view.

- Required very small space.

- It can also be designed for portable use.

- It has quick starting facility; the small diesel generator set can be started within few seconds.

- It can also be stopped as when required stopping small size diesel power station, even easier than it’s starting

- As these machines can easily be started and stopped as when required, there may not be any standby loss in the system.

- Cooling is easy and required smaller quantity of water in this type power station.

- Initial cost is less than other types of power station.

- Thermal efficiency of diesel is quite higher than of coal. 10. Small involvement is less than steam power station.

Disadvantages of Diesel Power Station

- As we have already mentioned, the cost of diesel is very high compared to coal. In other words the running cost of this plant is higher compared to steam and hydro power plants.

- The plant generally used to produce small power requirement.

- Cost of lubricants is high.

- Maintenance is quite complex and costs high.

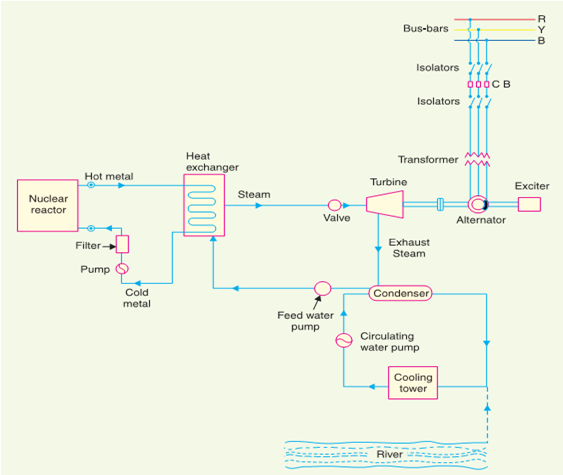

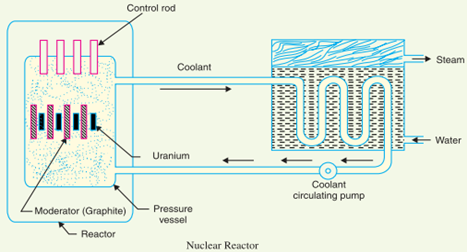

21. Explain the working of nuclear power station with the help of a neat layout?

OR

Draw a labelled schematic diagram of Atomic power plant and describe its working and explain the functions of nuclear reactor?

A generating station in which nuclear energy is converted into Electrical energy is known as Nuclear Power Station.

A nuclear power plant is a thermal power station in which the heat source is a nuclear reactor. Nuclear power plants heat produced during nuclear fission process. Heavy elements such as Uranium 235 & Thorium 232 are subjected to nuclear fission in a special apparatus known as reactor. The heat generated by nuclear fission is used to generate high temperature & pressure steam that drives a Steam turbine connected to a generator that produces electricity.

Main components of nuclear power plants:

- Nuclear Reactor: It is an apparatus in which nuclear fuel (U235) is subjected to nuclear fission. It controls the chain reaction that starts once the fission is done. If the chain reaction is not controlled, the result will be an explosion due to the fast increase in the energy released.

A nuclear reactor is a cylindrical stout pressure vessel and houses fuel rods of uranium, moderator & control rods. The fuel rods constitute the fission material and release huge amount of energy when bombarded with slow moving neutrons. Moderator consists of graphite rods/Heavy water which enclose the fuel rods. Moderator slow down the neutrons before they bombard the fuel rods. The control rods are of Boron / Cadmium are inserted into the reactor. Cadmium is a strong absorber of neutron and thus regulates the supply of neutrons for fission process according to the load variations. When the control rods pushed in deep, they absorb almost all neutrons and stops the chain reaction ie, the stops. The heat produced in the reactor is removed by the coolant, generally sodium metal and water is used. The coolant carries the heat to the heat exchanger.

2. Heat exchanger: The coolant gives up heat to the heat exchanger which is utilized in raising the steam. After giving up heat, the coolant is again fed to the reactor by use of pump.

3. Steam turbine: The steam produced in the Heat exchanger is passed to the turbine through a valve and work is done by the expansion of steam in the turbine. Exhaust stem from turbine is passed to the condenser. Condenser condenses the steam which is fed to the heat exchanger through feed water pump.

4. Alternator: The steam turbine is coupled to the alternator. The alternator converts mechanical energy into electrical energy. The output from the alternator is given to the bus-bars through transformer, circuit breakers and isolators.

22. Discuss the Advantages and Disadvantages of Diesel power station?

Advantages

- Space requirement of a nuclear power plant is less as compared to other conventional power plants is of equal size.

- A nuclear power plant consumes very small quantity of fuel. Thus fuel transportation cost is less and large fuel storage facilities are not needed.

- There is increased reliability of operation.

- Nuclear power plants are not affected by adverse weather conditions.

- Nuclear power plants are well suited to meet large power demands. They give better performance at higher load factors (80 to 90%).

- Materials expenditure on metal structures, piping, storage mechanisms are much lower for a nuclear power plant than a coal burning power plant.

Disadvantages

- Initial cost of nuclear power plant is higher as compared to hydro or steam power plant.

- Nuclear power plants are not well suited for varying load conditions.

- Radioactive wastes if not disposed carefully may have bad effect on the health of workers and other population. In a nuclear power plant the major problem faced is the disposal of highly radioactive waste in form of liquid, solid and gas without any injury to the atmosphere. Maintenance cost of the plant is high.

- It requires trained personnel to handle nuclear power plants.

23. List the important factors to be considered in the site selection of Nuclear Power Station?

- Availability of Water: Sufficient water is required for cooling purpose. So the plant site should be located where huge quantity of water is available. Eg: across a river

- Disposal of Waste: Bi product of fission process, is radioactive. Radioactive wastes if not disposed carefully may have bad effect on the health of workers and other population. In a nuclear power plant the major problem faced is the disposal of highly radioactive waste in form of liquid, solid and gas without any injury to the atmosphere. Therefore, the site selected for a such plant should have adequate arrangement for the disposal of radioactive waste.

- Distance from populated area: The site selected for the plant should be quite away from the populated area as there is a danger of presence of radio activity in the atmosphere near the plant.

- Transportation facility: Power station often requires the transportation of materials and machinery. Therefore, adequate transportation facilities must exist.

- Labour should be available at reasonable charges at the time of construction of the plant.

24. Write the Function of Moderator in Atomic Power Plant?

Moderator consists of graphite rods/Beryllium/Heavy water which enclose the fuel rods. Moderator slows down the neutrons in nuclear reactor. Moderators are made up of materials with light nuclei that do not absorb neutrons but slow down the speed of neutrons by a series of successive collisions.

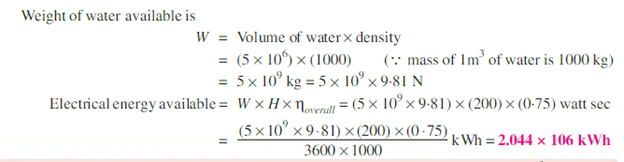

25. A hydroelectric generating station is supplied from a reservoir of capacity 5x 106 cubic metres at a head of 200 metres. Find the total energy available in Kwh, if the overall efficiency is 75 %?

II Unit – Economic Consideration of Electrical Power.

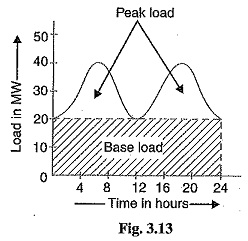

1. State the difference between base load and peak load?

Base load is the unvarying load which continuously occurs throughout the day on the station. While the term peak load refers to the variable peak demands of load, when the demand for electricity increases above the base load.

In the fig, 20 MW of load has supplied throughout the day is the base load. It is almost constant. Maximum load which is only for short duration is called Peak load.

2. Define a Tariff?

The rate at which electrical energy is supplied to a consumer is known as Tariff.

3. List the objectives of Tariff?

- Recovery of cost of capital investment on generating, Transmission, & Distribution Equipment’s.

- Recovery of cost of production, operation & Maintenance of equipment

- Recovery of cost of metering equipment, billing, collection cost etc..

- Suitable profit on capital investment.

4. Describe the desirable characteristic of a Tariff?

- Proper Return: The tariff should be such that it ensures the proper return from each consumer. In other words, the total receipts from the consumers must be equal to the cost of producing and supplying electrical energy plus a reasonable profit.

- Fairness: The tariff must be fair so that different types of consumers are satisfied with the rate of charge of electrical energy. Thus a big consumer should be charged at a lower rate than a small consumer. It is because increased energy consumption spreads the fixed charges over a greater number of units, thus reducing the overall cost of producing electrical energy.

- Simplicity: The tariff should be simple so that an ordinary consumer can easily understand it. A complicated tariff may cause an opposition from the public which is generally distrustful of supply companies.

- Reasonable Profit: The profit element in the tariff should be reasonable. The investment is relatively safe due to non-competition in the market. This calls for the profit to be restricted to 8% or so per annum.

- Attractive: The tariff should be attractive so that a large number of consumers are encouraged to use electrical energy.

5. Explain different types of tariff used in electrical power system? OR Differentiate Two part tariff & Maximum demand tariff?

1. Simple tariff:

- When there is a fixed rate per unit of energy consumed, it is known as simple tariff (Uniform Rate Tariff)This is the most simplest of all tariff.

- In this type, the price charged per unit is constant.

- It means, the price will not vary with increase or decrease in number of units used.

- In this type of tariff, there is no difference for small and big consumers.

- Same amount of rate is applicable for both the consumers. This is the disadvantage of this tariff rate.

Advantages

- Simplest method

- Easily understandable and easy to apply

- Each consumer has to pay according to his utilization

Disadvantages

- There is no discrimination according to the different types of consumers.

- The cost per unit is high.

2. Flat rate tariff:

- In this tariff, different types of consumers are charged at different rates of cost per unit (1kWh) of electrical energy consumed.

- Different consumers are grouped under different categories. Then, each category is charged money at a different uniform rate.

- The different rates are decided according to the consumers, their loads and load factors.

Advantages

- More fair to different consumers.

- Simple calculations.

Disadvantages

- A particular consumer is charged at a particular rate.

- Since different rates are decided according to different loads, separate meters need to be installed for different loads such as light loads, power loads, etc. This makes the whole arrangement complicated and expensive.

- All the consumers in a particular “category” are charged at the same rates. However, it is fairer if the consumers that utilize more energy be charged at lower fixed rates.

3. Block rate tariff:

- In this tariff, the first block of the energy consumed (consisting of a fixed number of units) is charged at a given rate and the succeeding blocks of energy) are charged at progressively reduced rates.

- Energy consumption is divided into blocks and the price per unit is fixed in each block.

- Example,the first 50 units (1st block) may be charged at 4 rupees per unit; the next 30 units (2nd block) at 3 rupees per unit and the next 30 units (3rd block) at 2 rupees per unit.

Advantages

- The consumer gets an incentive to consume more electrical energy. This increases the load factor of the system and hence the cost of generation is reduced.

Disadvantages

- Lack of measure of the consumer’s demand. This type of tariff is being used for the majority of residential and small commercial consumers.

4. Two – part tariff:

- When the rate of electrical energy is charged on the basis of maximum demand of the consumer and the units consumed, it is called a two-part tariff.

- In this tariff scheme, the total costs charged to the consumers consist of two components: fixed charges and running charges.

- It can be expressed as: Total Cost = [A(kW)+B(kWh)]Rs. Where, A = charge per kW of max demand and B = charge per kWh of energy consumed

- The fixed charges will depend upon maximum demand of the consumer and the running charge will depend upon the energy (units) consumed & running charges are due to the operating cost which varies with variation in generated (or supplied) energy.

- This type of tariff is mostly applicable to industrial consumers who have appreciable maximum demand.

Advantages

- It is easily understood by the consumers.

- It recovers the fixed charges which depend upon the maximum demand of the consumer but are independent of the units consumed

Disadvantages

- The consumer has to pay the fixed charges irrespective of the fact whether he has consumed or not consumed the electrical energy.

- There is always error in assessing the maximum demand of the consumer.

5. Maximum demand tariff:

- In this tariff, the energy consumed is charged on the basis of maximum demand.

- This is similar to that of Two part tariff. The max demand is calculated by installing maximum demand meter.

- Generally applied to large industrial consumers.

6. Power factor tariff:

- In this tariff scheme, the Power factor of the consumer’s load is taken into consideration.

- Power factor is an important parameter in power system. For optimal operation, the Pf must be high.

- A low power factor increases the rating of station equipment and line losses. Therefore, a consumer having low power factor must be penalized.

The following are the important types of power factor tariff:

(i) KVA maximum demand tariff: It is a modified form of a two-part tariff. In this case, the fixed charges are made on the basis of maximum demand in kVA and not in kW. As kVA is inversely proportional to power factor, therefore, a consumer having low power factor has to contribute more towards the fixed charges. This type of tariff has the advantage that it encourages the consumers to operate their appliances and machinery at improved power factor.

(ii) Sliding scale tariff: This is also known as average power factor tariff. In this case, an average power factor, say 0·8 lagging, is taken as the reference. If the power factor of the consumer falls below this factor, suitable additional charges are made. On the other hand, if the power factor is above the reference, a discount is allowed to the consumer.

(iii) KW and KVAR tariff: In this type, both active power (kW) and reactive power (kVAR) supplied are charged separately. A consumer having low power factor will draw more reactive power and hence shall have to pay more charges.

7. Define the term Connected Load?

- It is the sum of continuous ratings of all the equipment’s connected to supply system.

Example: Five 100 Watt lamps & 500 watts of a power point, Total connected Load = (100 x 5) + 500 = 1000 watts

8. Define Maximum Demand?

- It is the greatest demand of load on the power station during a given period.

It is the maximum load in kW which a consumer uses at any time.Maximum demand is always less than connected Load. Because all devices never runs at full load at the same time.

8. Define Average load and Load Factor?

Average load: The average of Loads occurring on the power station in a given period (Daily or Monthly or Yearly) is known as Average Load or Average Demand.

Daily Average Load = No of units generated in a day / 24 hours

No of units generated in a day = Daily Average Load x 24

Load Factor: The Ratio of Average load to the Maximum demand during a given period is known as Load factor.

Load Factor = Average Load / Maximum Demand

Load factor always less than one, because average load is smaller than Maximum demand. Higher the load factor, lesser the cost per units generated.

No of units generated in a year = Load factor X Maximum demand x 8760

9. Explain the following terms, (i) Demand factor (ii) Diversity Factor (iii) capacity factor?

(i)Demand factor: It is the ratio of maximum demand on the power station to its connected load.

Demand Factor = Maximum demand of a system / Total connected load on the system.

Demand factor is always less than one, because Maximum demand is smaller than total connected load. Higher the load factor

(ii)Diversity Factor: It is the ratio of the Sum of individual Max demands to the Max demand on power station is known as diversity factor

Diversity Factor = Sum of individual Max demands / Max demand on power station

- Maximum demand on power station always less than the sum of individual maximum demand.Diversity factor will always greater than 1. Greater the diversity factor, The cost of generation is lesser

(iii)Capacity factor: It is the ratio of Actual energy produced to the maximum possible energy that could have been produced during a given period.

Capacity factor = Actual energy produced / the max. energy that could have been produced

Capacity factor = Average demand / Plant capacity

10. List out the major costs associated with the generation of electric power? OR

Explain the difference between fixed cost and Running cost in generating station?

The total cost of power (electrical energy) generation comprises of the following charges:

Fixed cost: It is the cost which is independent of maximum demand and units generated. Fixed cost includes:

- Annual charges of the central organization management

- Salary of the employees (usually higher officials)

- Interest on the land costs

All of these costs are fixed, and hence, fixed cost remains constant under all conditions.

Semi fixed cost: Such charges are independent of the energy (kWh) generated but depend upon the maximum demand. Higher the max demand, the greater the semi-fixed costs. Since these depend upon the size (and cost) of installation which again depends on the max demand. Semi-fixed cost includes:

- Interest and depreciation on the capital costs on the land, the buildings (construction costs), taxes, salaries of management & clerical staff and the costs of the equipment’s of the electricity.

- Such interest may range up to 8% depending upon the market conditions.

- Due to wear and tear, the depreciation occurs and such depreciation costs are also included in the fixed and semi-fixed charges.

Running or Operating cost: Running charges will depend mainly upon the energy (in units or kWh) generated by the plant. If the power station generates more units, it will have higher running cost and vice versa. Running cost includes,

- Cost of fuel

- Cost of maintenance and repairs: As a plant ages, wear and tear occur, and maintenance is needed. The wear and tear of the plant necessitate the use of lubricating oil which has its own cost.

- Salaries of the operating staff.

11. Draw a daily load curve of a power station and explain importance of it?

- The Curve showing the variation of load on the Power Station with reference time is known as a Load Curve.

- The Load Curve is a Graph, which represents load on the generation station (the load is in kW/MW) recorded at the interval of half hour or hour (time) against the time in chronological order.

- We have to draw the load curve on daily basis data, weekly, monthly basis data. The curves showing the variation of load on the power station with respect to time is known as load Curves.

- The area under the daily load curve gives the number of unit generated in the day. Unit generated/day= Area (in kWh) under daily load curve.

- The highest point on the daily load curve represents the maximum demand on the station on that day.

- The area under the load curve divided by the total number of hours gives the average load on the station.

Average Load = Area (in kWh) under daily load curve/24 hours

III Unit – Electrical Power Transmission

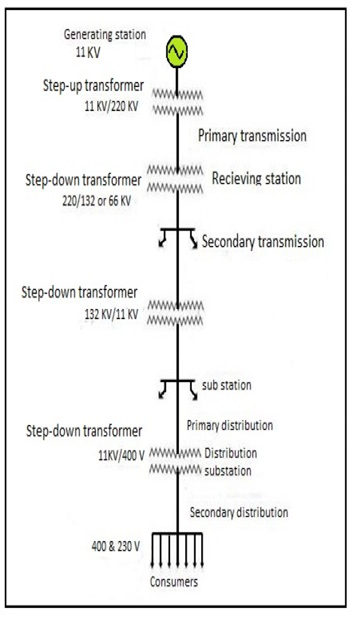

1. Draw a single line diagram of a typical AC Power supply scheme with electrical power generation, Transmission and Generation?

Electrical energy from a generating station is transmits & delivers to the consumer’s by using transmission system and distribution system.

Power Supply System Consist of Following Stages:-

- Generating station: Electrical energy produced in generating station by alternators. The usual generating voltage is 11 KV. For economy of transmission of power, the generating voltage is stepped up to 132 kV or more at the station with the help of 3 phase step up transformers.

- Primary Transmission: The electrical power at 220 kV is transmitted by 3 phase 3 wire overhead system to the outskirts of the city. This forms the primary transmission.

- Secondary transmission: primary transmission line is connected to the Receiving Station. At the RS voltage is step-down to 132/66kV using step don transformer and that voltage is supply to the substation through the transmission line of 3 phase 3 wire system, it’s known as secondary transmission.

- Primary distribution: The secondary transmission line is terminates at the substation. Where Voltage is step-down to 11kV using step down transformer and that voltage is supply to the distribution substation through the transmission line of 3 phase 3 wire system. 11KV is directly given to the HT(high tension) consumer like industrial area, known as a primary distribution line. Electrical power from primary distribution line is deliver to the various distribution stations is located near to the consumer area.

- Secondary distribution line: In distribution substation, the voltage is step down 11KV to 400v or 230V by Transformer, that voltage is deliver to the consumer or load center that known as secondary distribution line. Secondary distribution system is 3 phase, 4 wire system.

2. Explain the classification of Overhead transmission line based on length, and voltage?

- Short transmission line: When the length of the line is up to about 50 km, the line considers as a short transmission line. The line voltage is less than 20 kV. The capacitance effect in short overhead line is neglected. Because due to the small length and lower voltage, the capacitance effect is very small. Hence, in short, overhead transmission line, the capacitance effect is neglect. Therefore, while designing, modeling and studying the performance of the short line, only resistance and inductance are taken into account.

- Medium transmission line: When the length of the line between 50 km to 150 km and the line voltage is between 20 kV to 100 kV, this type of overhead line consider as a medium transmission line. In this type of line, the capacitance effect cannot be neglect. Hence, while studying the performance of the line, the capacitance effect must include.

- Long transmission line: When the length of the transmission line is more than 150 km, the line considers as a long transmission line. In this type of transmission line, the voltage is more than 100 kV. For the modeling and designing of the long overhead transmission line, the capacitance effect is taken as uniformly distribute over the entire length of the line.

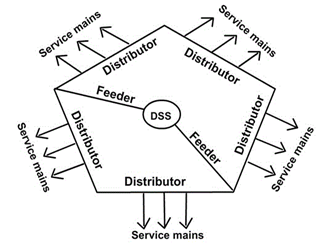

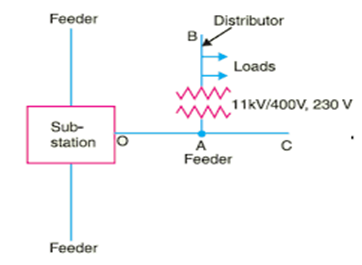

3. Draw the schematic diagram of Distributor-feeder-service mains?

The part of power station. Which distributes electric power for local use is known as Distribution system. It consists of Feeder, Distributor, and the service mains.

Feeder : Feeder is the conductor which connects the substation to the area where power is to be distributed. The main consideration in the design of feeder is current carrying capacity. In fig. Feeders are SA, SB & SC.

Distributor:Distributors is the conductor which tappings are taken for supply to the consumers. The main consideration in the design of distributor is Voltage drop. In fig.. Distributors are BC, CD, AD…

4. List out the Advantages of High voltage AC Transmission voltage?

- Reduce the volume of conductor material.

- Reduce the transmission conductor cost.

- Decreases the percentage line drop.

- Increase the transmission efficiency.

5. List out the Disadvantages of High voltage AC Transmission voltage?

- Increased the cost of insulating the conductors.

- Increased the cost of switch gear.

- Increased the Transmission tower height.

6. Compare Overhead and Underground transmission system?

| Particular | Over head system | Under ground system |

| Public safety | Less safe | More safe |

| Initial cost | Less expensive | More expensive |

| Faults | Fault occur frequently | very rare chance of fault |

| Flexibility | More flexible | Less flexible |

| Fault location | Easily located | cannot easily located |

| Repairs | Easy | Difficulty |

| Useful life | Less | More |

| Maintenance cost | More | Less |

| Interference with communication line | More | Less |

| Appearance | Not good | Good |

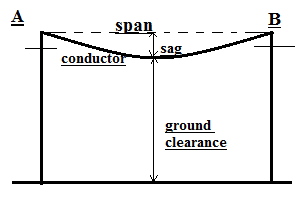

7. Define Sag in overhead line. Explain the factors effecting sag in OH line?

Sag in Transmission Line:

- The difference between in level between points of supports and the lowest point on the conductor is called Sag. The horizontal distance between two electrical supports is called the span.

- When overhead line conductor is hung between two supports, the conductor takes the natural catenary shape.

Factors Affecting the Sag in an OH Line:

- Weight of the conductor: Sag of the conductor is directly proportional to its weight. The weight of the conductors is increased due to ice loading.

- Length of the span: Sag is directly proportional to the square of the span length. Longer span gives more sag.

- Tensile strength: The sag is inversely proportional to the tension in the conductor.

- Temperature: The sag is reduced at low temperatures and is increases at higher temperatures.

- Wind pressure: It increases sag in the inclined direction.

- Ice weight: Sag of the conductor is directly proportional to its weight. The weight of the conductors is increased due to ice loading.

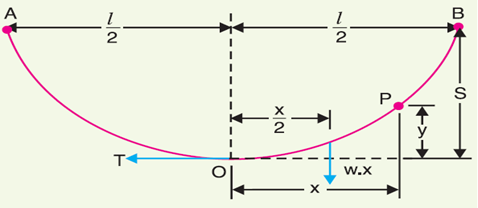

8. Express the calculation of Sag in equal and Unequal levels?

In an overhead line, sag should be so adjusted that tension in the conductors is within safe limits. The tension is due to the effect of conductors weight, effects of wind, ice loading and Temperature variations.

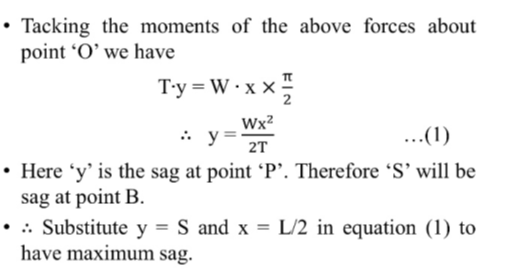

When Supports are at equal Levels: Consider a conductor between two equal supports A and B with O as the lowest point of conductor. Consider a point P on the conductor.

Taking the lowest point O as the origin, let the coordinates of point Pat x and y. assume the curved length is small and equal to x. two force acting on the portion OP of the conductor are,

- The weight wx of conductor acting at a distance X/2 from O.

- The tension T acting at O.

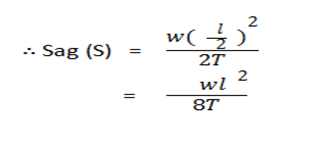

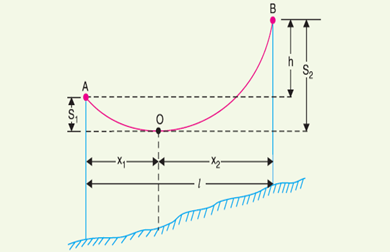

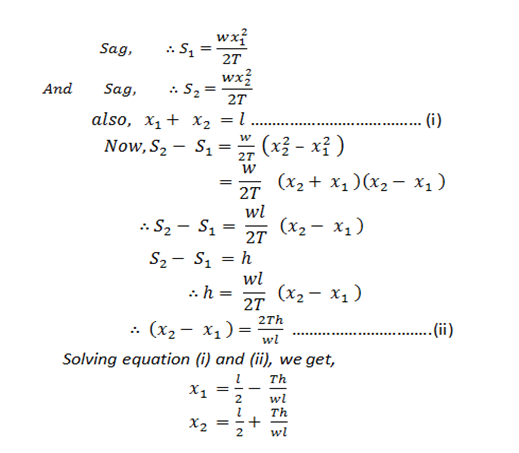

When Supports are at Unequal Levels:

In hilly areas, we generally come across conductors suspended between supports at unequal levels. Conductor suspended between two poles A and B which are at different levels.

If w is the weight per unit length of the conductor, then

Having found x1 and x2, the values of S1 & S2 can be easily calculated.

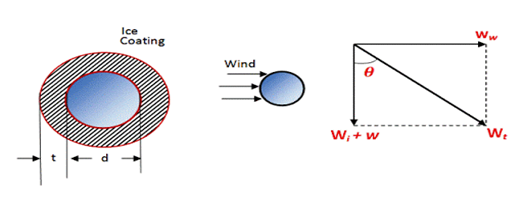

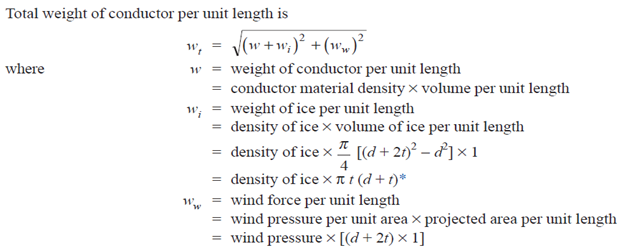

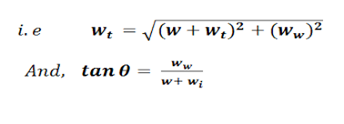

9. Explain the effect of wind and ice coating on overhead transmission lines?

When the transmission line is coated with ice and simultaneously subjected to wind pressure, the thickness and size of the conductor increases. This thickness depends upon weather conditions. This cause increase in weight of the conductor. Increase in weight increases the vertical sag.

Normally the net wind pressure direction is taken into the horizontal direction to the line conductor. The direction of Ice coating and the original conductor weight pressure in the vertical direction. So the total force on the high voltage line conductor is the vertical sum of the horizontal and vertical forces.

The phase diagram of the weight and pressure applied to the conductor shown in below image

The sag equation for transmission line is as following,

S =Wtl²/8T

S represent the slant sag in a direction making an angle θ to the vertical.

10. Explain methods of AC distribution system based on connection scheme?

The following connection schemes of distribution system are generally employed:

- Radial System: In a radial system, separate feeders radiate from a single sub-station and feed the distributors at one end only. A single line diagram of a radial system for AC distribution is shown in the figure.

Here substation supplies power to a distributor AB at end A through feeder OC. This system is only employed when power is generated at low voltage and the substation is located at the center of the load.

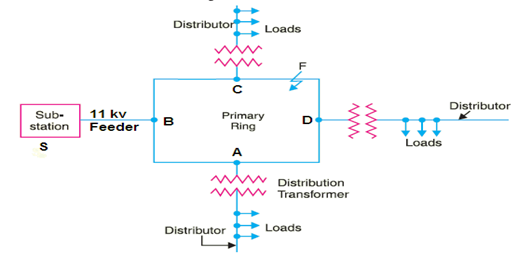

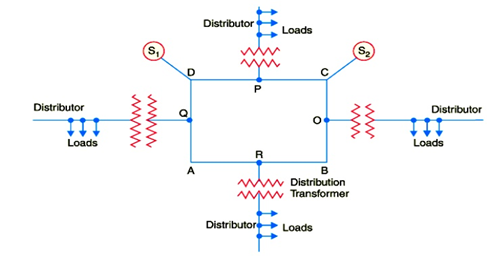

Ring Main System: In this system, primaries of distribution transformers form a loop. it forms a complete ring and hence the name ring main system. Fig. shows AC ring main system, where BCDAB is the closed feeder supplied by the sub-station S at point B. The various distributors are connected to points A, C and D of the feeder.

Inter Connected System: In this system, the feeder ring is energized by two or more than two generating stations or substations. The figure shows the single line diagram of AC interconnected system, where the closed feeder ring ABCA is supplied by two generating or substations S1, and S2, at point D and C respectively. Distributors are connected to the feeder at point R, Q, P and O.

11. Explain different causes of failure occurs in insulators?

- Deterioration by cracking of the porcelain.

- Porosity

- Puncture of weak porcelain: In case of insulator puncture, electrical discharge occurs from conductor to pin through the body of the insulator. Sufficient thickness of porcelain (or the insulator material) must be provided to avoid a puncture breakdown. When such breakdown is involved, the insulator is permanently damaged.

- Shattering by power arcs.

- Flash over caused by dust deposits: Flash-over: In insulator flash-over, electrical discharge occurs by forming an arc between the line conductor and the insulator pin (which is connected to the cross-arm). The discharge jumps through the air surrounding the insulator following the shortest distance. In case of a flash-over, the insulator continues to act according to its designed capacity unless it gets destroyed due to the excess heat.

- Failure from mechanical stresses.

- Short circuits by birds & similar objects.

Recent Comments